It is certainly no ordinary desire to build a car from scratch let alone an “ultra” car with performance figures that promise to leave everything, except possibly a jet fighter, in its dust.

But Spyros Panopoulos is no ordinary dreamer – even if the car, the Chaos, promises to be something out of this world and it will carry the label: Made in Greece. And it is all made in Greece from conception, to design, to manufacture. All the components are made using the latest technology and production processes that belong more to tomorrow than to the present.

The project that gets him up at 4.30am every day has been in the making for the past three years. The target, he tells Neos Kosmos, is to get the Chaos finished and tested in time for the Geneva International Motor Show in March 2021.

Under the current classifications the Chaos would share space with hyper cars such as a Bugatti Veyron, a top-end Lamborghini, Ferrari or Aston Martin’s Valkyrie . If Mr Panopoulos has anything to do with it, in the land of the Hyper Car, the Ultra Car will rule and the Chaos will be king.

However, while the Chaos performance figures are gob-smacking, what really stands out are the car-making processes that Spyros Panopoulos Automotive, of which Mr Panopoulos is CEO, has developed and the materials used to make the car unique. The results are components that are lighter, stronger and with significantly improved performance figures.

Over the years, Mr Panopoulos, has developed a big name in turning up cars to perform way past their original design limits. His patented components have been used by Formula One, World Rally Championship and other racing formulas to boost their performances.

He has developed high-performance motorsport electronics and automotive control tuning systems. His products have been used by the Greek defence forces and have found their way to motorcycles, boats and jetskis.

As a driver he has broken four drag racing world records with his re-imagined Mitsubishi EVO, only the chassis remains Mitsubishi’s. One of the key features on this car, among many of his other innovations, is his patented turbocharger. The design and development of this car was all done in his factory in Athens. The 1788cc engine that he developed delivers 2880 HP at 14,100 RPM which is a world record in itself.

The automotive knowledge he has developed over the years has all been ploughed into Project Chaos. Spyros Panopoulos Automotive has a staff of 22 people, of whom nine are dedicated to Chaos. If it proves successful, Mr Panopoulos will be hiring several hundred people.

What the Chaos can do is partially informed by his experience as a driver. A select few can tell you what it is like to be in car that goes from standing still to 100km/h in 1.8 seconds. The car will reach 0-200km/h in 3.9 seconds and its top speed will be 500km/h. And hitting those speeds will generate about 3Gs, a gut-punch, dragster thrill that Mr Panopoulos says you don’t get in other hyper cars.

Yet Mr Panopoulos maintains that the Chaos is not meant to be a racing car only, but a car that anyone can drive because the driver can recalibrate the car’s electric engine control unit to deliver anything from a “sedate” 500 Horse Power for a daily commute to the 3000 HP that could prematurely age you.

“You will be able to change the performance through the onboard computer,” he told Neos Kosmos. “The driver can adjust the power from the car’s display panel or even from a phone application.”

The Chaos will come in versions. Both use a turbocharged four-litre, V10 engine with titanium camshafts, Inconel valves, 3D printed pistons and rods on a monocoque chassis.

The “lower” spec version pushes 2,000 HP while revving through to 11,000 Revolutions Per Minute (RPM). It’s engine will use titanium rods and pistons and standard petrol.

The higher spec version which will reach to 12,000 RPM and deliver 3,000 HP using e85 fuel. This version will come with ceramic pistons carbon-fibre rods and injectors.

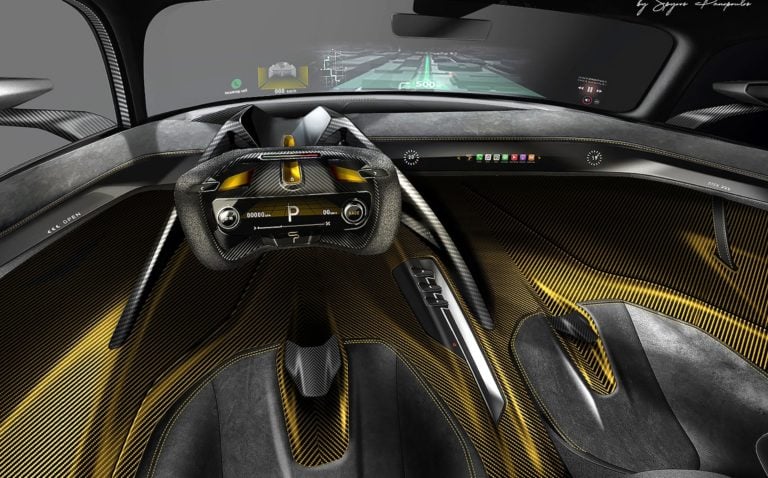

There will be no buttons to push in the cockpit as the driver will be using virtual-reality glasses to activate functions in the car which include an 5G-augmented platform. The car will weigh just 1,280kg.

The Chaos, he says, is not just about speed and acceleration but also the application of cutting-edge technology in its production, and in the way it drives.

Otherworldly performances are being matched by otherworldly production methods. The Andiaplasi system that Mr Panopoulos pioneered utilises 3D printing for the uniquely designed components. Most of the car’s components were made using Andiaplasi.

The Chaos is made with the latest materials – Xylon carbon fibre, ceramics, kevlar, titanium and magnesium – that are cutting edge and are more likely to be found in high-end motor car racing and other manufacturing processes.

Mr Panopoulos who was born 1978 in Athens. In the mid-1990s he came to car production through computer programming. He learnt to develop software and hardware

“I was into computers starting from low-level programming languages. My father, who was in the Greek Air Force, had a Golf GTI which did not have an onboard computer. So I made my own for the car,” he said.

Greece is not a country with a heritage in car manufacture. In 1997, the young man went to Europe to get the hardware he needed to develop his cars. In 1999, he approached a leading motorsport company who gave him an electronic control unit through which he developed his own software. It is a relationship he has retained to this day.

READ MORE: Car designer pays computer homage to Sir Stirling Moss

Over the next two years, Mr Panopoulos travelled around the world building his reputation as a tuning specialist. On his return to Greece, he founded Spyros Panopoulos Automotive to carry high-performance parts research and development.

“I worked in Formula One and saw a lot of Greeks were doing good work in dynamic positions for leading organisations. Greeks don’t look at doing just the one job that they are paid to do like robots. Greeks are great multi-taskers.”

“When I was overseas, all the Greeks that I met wanted to go back to Greece. I felt I must go back and I want the Greeks to come back. ‘” he said.

Mr Panopoulos said he had spurned offers from foreign companies to use their materials opting to develop the Chaos in Greece and not have someone else claim credit for its manufacture.

He said he had received many offers from overseas companies to take over his projects. He rejected the offers because he wanted the work to be wholly Greek.

“In the US I was offered $10 million to setup the hyper car. But my family and my friends are here in Greece and I will never leave my country,” he said. “It was not a financial consideration but an ethical one,” he said.

The money he hopes to make will not come from the sale of the car itself, it already has a buyer for $5,5million, but from the processes and materials he has developed in making the Chaos.

He plans to create the Spyros Panopoulos Group of Companies, that will offer high-quality and innovative services for aviation, defence and motorsport applications. Already he has machinery in place that is not available elsewhere in Europe.

Mr Panopoulos said the group will soon boast the most advanced Computer Numerical Control (CNC) facility in the world that will dramatically enhance production.

READ MORE: Greek car designer George Koukos talks about cars, rembetiko, and his homeland

The Chaos will not be the only car that Mr Panopoulos will unveil in Geneva next year. He is more guarded about another car, the Apeiron, that he will unveil next to the Chaos.

The Apeiron, he says will be 10 years ahead of its time and will be made of materials that will negate aerodynamic difficulties. It will be able to alter its shape to maximise the aerodynamics in any given situation.

“It is a beautiful car and something no one has seen before. You will see only one surface and no turning wheels,” he said. There are no further hints on offer.

“My hope is that when the cars go to Geneva, they will put Greece at the centre of technology and innovation. This is my passion. I am at work by 5am every day. I wake to go to work, I love it.”

Chaos: The key features

- Engine will be a 4-litre twin-turbo V10 at 90 degrees.

- Aluminium 5-axis engine block and cylinder heads

- 12.3:1 compression ratio.

- 20 fuel injectors (10 direct injection).

- 40 valves.

- Titanium camshafts.

- Titanium Inconel valves.

- Eight-speed dual-clutch transmission.

- Torsen differential going out to all wheels with 65 per cent of power to rear wheels and 35 per cent to the front.

- Twin carbon-fibre turbochargers with Titanium and ceramic compound turbine wheels.

- Chassis: Monocoque zylon with the body parts made of carbon-fibre and kevlar

- Mechanical parts are from ‘anadiaplasi’ 3D printed titanium and magnesium.

- 3D printed titanium exhaust, magnesium brake calipers and titanium wheels, along with the carbon fibre turbochargers, conrods and crankshafts.

- Ceramic brakes with 420mm discs and titanium claws.

- Wheel rims 3D printed titanium or carbon fibre.

- Tyres 355 mm in diameter. 3D printed taillights, sharp LED taillights.

- Monocoque chassis.

- Low-slung, mid-engine design.

- The car also uses a new amorphous new steel alloy SAM2X5-630 made that uses using glass matrix composites to create a new type of steel that is resilient to shock and able to bounce back into shape.

The 2,000 HP version:

- Runs on normal petrol.

- 11,000rpm

- Andiaplasi 3D printed titanium pistons and rods.

The 3,000 HP version:

- will use E85 fuel

- Andiaplasi 3D-printed ceramic pistons and carbon fibre rods.

- 12,000 rpm

- Ceramic pistons and Carbon fibre injectors.